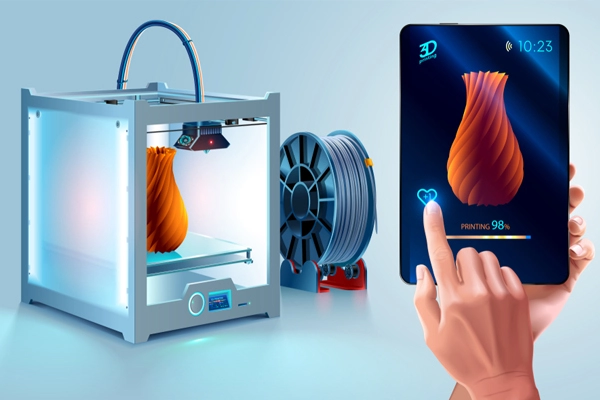

3D printing is a manufacturing process used to produce 3D objects from digital files. This technology is based on adding technology to the material, where objects are created by accumulating thin layers of material according to the 3D design created by CAD software.

The 3D printing process involves many different technologies, including FDM printing which uses plastic as the raw material, SLA printing which uses resin as the raw material, and SLS printing which uses nylon powder as the raw material.

3D printing is used in many applications, including mechanical parts manufacturing, tool and die manufacturing, jewelry and fashion manufacturing, prosthetics manufacturing and model design.

What technologies are used in 3D printing?

There are many technologies used in 3D printing, which include:

- Fusion deposition imaging (FDM): This is a popular technology that uses plastic as a raw material for the 3D printing process.

- Liquid Laser Painting (SLA): This is a technique that uses a laser to burn resin in places where the previous layer is painted.

- Fusion Laser Scanning (SLS): This is a technique that uses a laser to melt nylon powder and form the desired piece.

- Digital Light Printing (DLP): This is a technology that uses powerful light to cure the resin where the drawing is made.

- Powder photography: A technique that uses powder instead of liquid or wire to create pieces.

- MJP: This is a technique that uses many fine printer heads to add the perfect layers at the same time.

- Transformation Imaging (LMT): A technique that uses Mauhaus wax to create 3D models.

These technologies differ in the way they create parts, the material used in production, the cost of the printer, and the type of parts that can be produced.

How do I create a 3D file for use in 3D printing?

A 3D file can be created for use in 3D printing using CAD (computer-aided design) or 3D design programs, including:

- Tinkercad: It is an easy-to-use online 3D modeling software.

- Fusion 360: It is an advanced CAD program that allows users to create 3D designs and convert them into printable files.

- SolidWorks: It is a CAD program commonly used in industry and mechanical design that allows the creation of 3D designs.

- SketchUp: It is a 3D design program that allows users to create 3D designs easily and simply.

- Blender: It is a 3D modeling program commonly used in film and animation making, and it also allows the creation of 3D designs.

- AutoCAD: It is a popular CAD program used in many applications, including architectural and engineering design, and also allows the creation of 3D designs.

These programs can be downloaded and used to create 3D files for use in 3D printing. It may take some time to learn and practice these programs, but they will help you create unique, custom designs for use in 3D printing.

What materials can be used in 3D printing?

Many materials can be used in 3D printing, including:

- PLA (polylactic acid): It is a biodegradable biomaterial widely used in the 3D printing industry due to its ease of printing and low cost.

- ABS (Acetal Butadiene Styrene): It is a plastic characterized by hardness and durability and is used in many applications such as making interior parts of cars and electronic equipment.

- PETG (triethylene glycol): It is a transparent plastic material that can be printed 3D and is used in the manufacture of many products such as food, drinks, and medical packaging.

- Nylon: It is a strong and durable polymer and is used in many applications, such as making mechanical parts and parts used in cars.

- TPU (thermoplastic urethane): It is a 3D printable rubber material and is used in the manufacture of shoes, covers, and medical parts.

There are also many other materials that can be used in 3D printing, such as stainless steel, titanium, treated wood, fiberglass, and carbon fiber.

How do I know which type of material is suitable for my 3D printing project?

You can choose the right material for your 3D printing project by considering a range of factors that include:

- The nature of the project: For example, if the piece to be printed will be used outdoors, weather-resistant materials may be used. If the project is to produce small parts, other materials that have high precision and precision can be used.

- The required characteristics of the piece: For example, if the project requires high strength and rigidity, materials such as ABS or Nylon can be used. If the project requires high flexibility and elasticity, materials such as TPU can be used.

- Printer capacity: You must check the ability of your 3D printer to print the material you wish to use.

- Cost: You must take into account the cost of the materials required to print the project and ensure that it is appropriate for your budget.

When choosing the right material, you should also consider your 3D printer settings and know how to configure the printer and the ideal settings to achieve the best results.

How much does a 3D printer cost?

The cost of 3D printing printers varies greatly depending on the size, resolution, materials used in printing, as well as other technical features that the printer contains. Here are some common options and prices:

- Hobbyist 3D Printers: These printers range in price from $100 to $1000.

- Consumer 3D Printers: The prices of these printers range from 500 to 5000 US dollars.

- Industrial 3D Printers: The cost of these printers starts from 10,000 US dollars and reaches hundreds of thousands of dollars.

It is important to take into account that the cost of the printer is not the only expense, as you must take into account the cost of the materials that you will use in printing and the auxiliary software for designing 3D models. It’s also worth keeping maintenance and repair costs in mind when purchasing a 3D printer.

What are the best 3D printers on the market?

There are many excellent and popular 3D printers on the market, ranging in different sizes, prices, and technologies. Among the best 3D printers on the market currently are:

- Ultimaker S5: This printer has a large size and high resolution and comes with a wide range of technical features and great characteristics.

- Prusa i3 MK3S: This printer is considered one of the best economical options on the market, and is distinguished by its accuracy and high speed.

- Formlabs Form 3: It uses LFS (Low Force Stereolithography) technology, which provides extremely high resolution and superior printing quality.

- LulzBot TAZ 6: This printer is distinguished by its reasonable price, large size, and flexibility in printing on a wide range of materials.

- Creality Ender 3: It is an economical entry printer, characterized by high accuracy and ease of use.

- MakerBot Replicator+: This printer comes with high-quality printing and large size and is suitable for use in companies and institutions.

It is important to know that choosing the ideal printer depends on your project requirements and budget.

Can I use 3D printing to manufacture mechanical parts?

Yes, 3D printing can be used to manufacture mechanical parts. In recent years, 3D printing technology has become more widespread and used in manufacturing, thanks to its ability to produce parts with fine details and complex configurations.

3D printing is used to manufacture mechanical parts in many fields, such as the medical industry, aerospace industry, and engineering industry. If you want to use 3D printing to manufacture mechanical parts, you will need to use 3D design software to create CAD files and then convert them into 3D printable files. You will also need a 3D printer and the appropriate printing materials to manufacture the mechanical parts.

Can 3D printing be used for industrial manufacturing?

Yes, 3D printing can be used in industrial manufacturing. For example, 3D printing can be used to produce molds and tools that are used to make metal or plastic parts.

3D printing can also be used to manufacture tools used in molding processes, such as molds and tools used in injection and compression. In addition, 3D printing can be used to manufacture small and medium-sized mechanical parts that are used in industry.

By using 3D printing in industrial manufacturing, it is possible to save costs and time, reduce material waste, and improve efficiency in the manufacturing process.

What print sizes are available for 3D printers?

The print sizes available for 3D printers vary depending on the type of printer and manufacturer. 3D printers can be found in a variety of sizes, from small ones with a print area of up to 100mm x 100mm x 100mm, to large industrial printers with a print area of over a meter in one direction.

Medium-sized 3D printers are currently available that have a print area of between 200mm x 200mm x 200mm and 300mm x 300mm x 300mm, and these sizes are suitable for a wide range of home and commercial applications.

In general, choosing the size of the 3D printer depends on the size and type of parts that you want to produce and design using 3D printing. If the parts are small in size, it may be appropriate to use a small 3D printer, while if the parts are large in size, it may be necessary The use of large industrial 3D printers.

How long does it take to 3D print to produce a part of a given size?

3D printing time depends on the size of the part to be produced, and the speed of the 3D printer used. Printing time is usually estimated based on the printing rate of the 3D printer and the size of the part required.

For example, a small-scale part produced using a medium-speed 3D printer may take 1 to 2 hours, while a large-scale part produced using a large industrial 3D printer may take several days.

Moreover, the printing time may also be affected by other factors, such as the type of raw materials used for printing, the printing resolution required, and the complexity of the design. Therefore, it is advisable to speak with your 3D service provider or 3D printer manufacturer to get an accurate estimate of the printing time for a specific part.

SAMEEM, Digital Marketing Agency in the Middle East, has been involved in design, marketing, creating and promoting for more and ambitious brands since 2010.